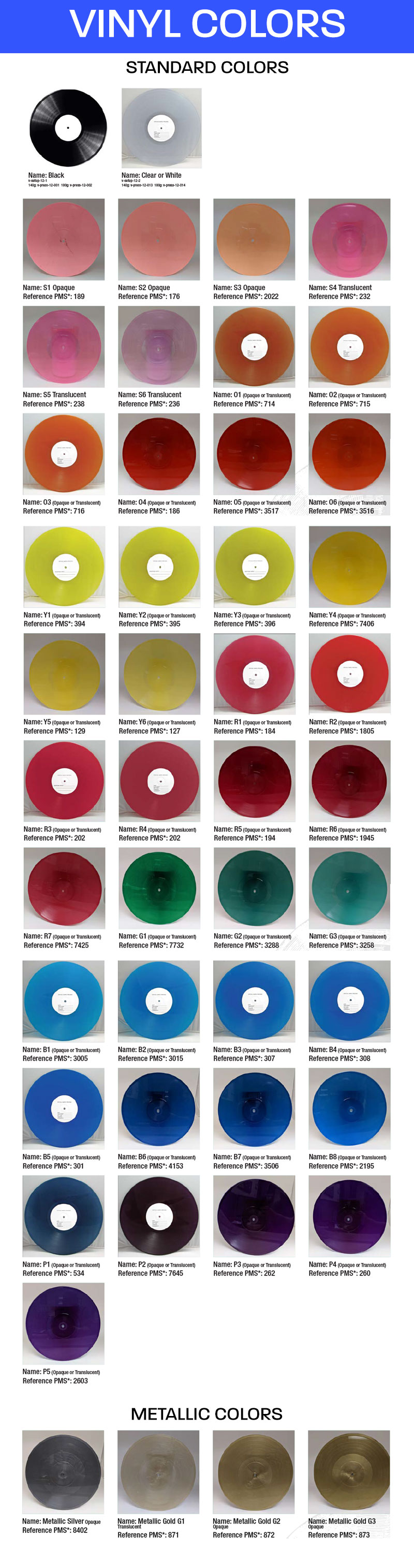

We can mix just about any Pantone color you want. We also have a wide range of special effects!

A few notes about vinyl labels:Labels are not adhesive labels - they are pressed into the vinyl at high temperature. Most labels will be off-white due to the baking process. On small orders we can use adhesive stick-on labels. |

Premastering is getting your audio ready for the lacquer cutting engineer. You can skip this step if your audio is already mastered and you supply an accurate cue sheet.

A cue sheet must be supplied for the cutting engineer to follow so he knows when to add the spiral between songs. Here is a document you can download and return with your audio files.

Stampers Your lacquers are sent to an electroplating facility to make metal stampers. One stamper is required for each side of your expedurlrecord, and each stamper is good for about 1000 to 1200 regular-weight vinyl records. If you want to make 2000 records, you must buy 2 stampers per side. For heavy-weight 180-gram records, each stamper is only good for about 500 to 600 records. Stampers are only guaranteed for the first run. Our standard packages include the 2-step stamper process so we can make several stampers from one lacquer. If you anticipate sales of up to 6000 units you can opt for 3-step plating. Test Pressing Once the stampers are ready, it is customary to make test pressings. You can skip this step at your risk (you benefit by saving time and money). The main risks are that there is a skip in the record or some excessive distortion. The louder the record, the greater the risk of distortion or skipping. But if the level is too low, the surface noise will be more apparent. The cutting engineer is trying to find the sweet spot where the record is as loud and good-sounding as possible without the needle jumping out of the groove. In practice there is only a problem with skipping in around 1 out of 1000 cuts, and if the engineer knows there is no test pressing he can hold back the level by 1 or 2 db to reduce the risk. Ticks and pops We wish our vinyl could be perfect, but that just isn't realistic. There will be some minor surface noise. Paper Labels Paper labels are required for each side of your record. You supply the artwork. Please advise if you want 1 colour, 2 colour, or full colour labels. We can also supply plain white labels, and on small runs it may be cost-effective to put printed adhesive labels over the white labels. Inner Sleeves Plain white paper sleeves are included with your records. You can upgrade to poly-lined sleeves, poly sleeves, or custom-printed inner sleeves. Jackets We also print full-colour cardboard jackets with your artwork. Our jackets are printed in Canada. Pressing Once you have approved your test pressing the machines are started to press your records. Packaging and shrinkwrap Your records and jackets are then inspected, assembled, and shrinkwrapped. Boxing and shipping Finally your records are packed into shipping cartons and shipped to you or your distributor. Prices Don't hesitate to contact us for a custom quote on record pressing! Toronto 647.478.4273 / Montreal 514.878.8273 / Toll-free North America 800-777-1927 * NB: Turntimes are only estimates and targets. The turntime is not guaranteed and we are not liable for any "lost sales" or other expenses due to missing your release date. If lacquers or stampers have to be redone this adds some time to the process. Final quantity may vary up to 10%. It is standard practice for the customer to be billed for any extra copies that are shipped. In the event of a shortage we will refund the difference. We recommend keeping this in mind when placing your order quantity.

|